Product Details

Product Introduction

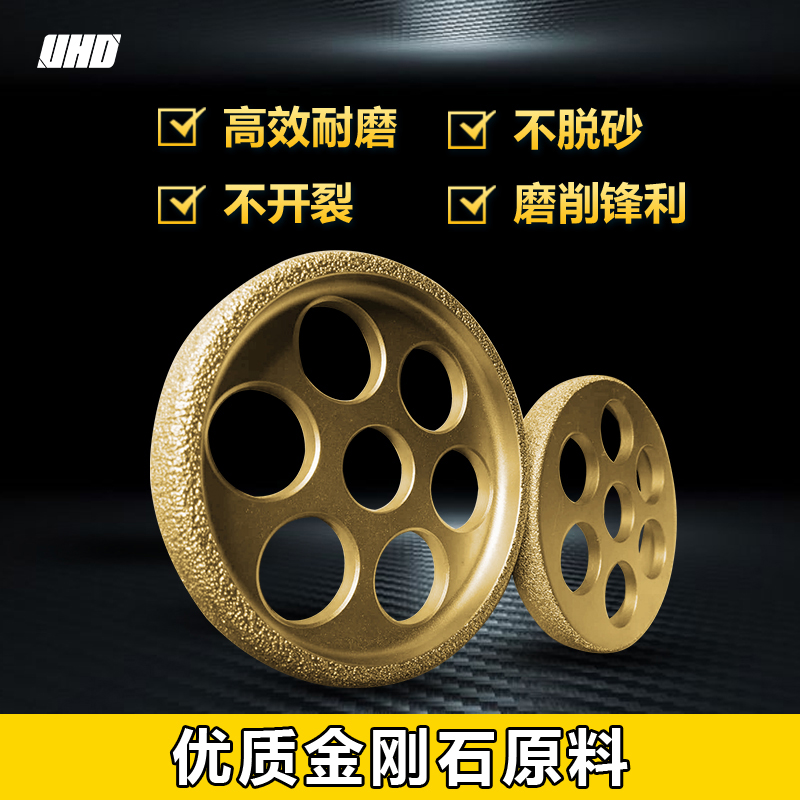

In response to the processing needs of hard materials such as ductile iron, gray iron, ceramics, and rubber, Henan Youde Superhard Material Tools Co., Ltd. has carefully launched the 400-brazed diamond grinding wheel. This grinding wheel adopts advanced vacuum brazing cloth technology, combined with high-quality diamond raw materials, which can provide sharp cutting performance during the grinding process, reduce dust emissions during workpiece processing, and is more environmentally friendly. The grinding wheel exhibits significant wear resistance and is not prone to cracking and desanding, ensuring a greatly extended service life. These characteristics enable the 400-brazed diamond grinding wheel to not only improve production efficiency, but also improve the quality of workpiece processing while effectively controlling costs. The products provide a variety of choices in size and specifications to meet the individual needs of different customers. They are ideal superhard grinding tools for metal processing, stone processing and other industries. The product has obvious cost-effectiveness advantages, which can significantly reduce the frequency of tool replacement and provide customers with cost-effective cutting solutions.

Advantages and features

1. Use advanced vacuum brazing technology to ensure a stronger bond between diamond particles and the grinding wheel matrix; 2. Use high-quality diamond raw materials to achieve sharp grinding and improve processing efficiency; 3. Reduce dust emissions during workpiece grinding, complying with environmental requirements ; 4. Excellent wear resistance increases the service life of the grinding wheel and reduces the frequency of replacement; 5. Diversified sizes and specifications to meet different process requirements; 6. Economical and efficient, significantly reducing long-term operating costs.

Application Scenario

1. Processing of ductile iron and gray iron; 2. Grinding of ceramic products; 3. Stone processing field; 4. Fine processing of rubber materials; 5. Suitable for grinding of high-hardness materials such as metal processing and automobile manufacturing.