Product Details

Product Introduction

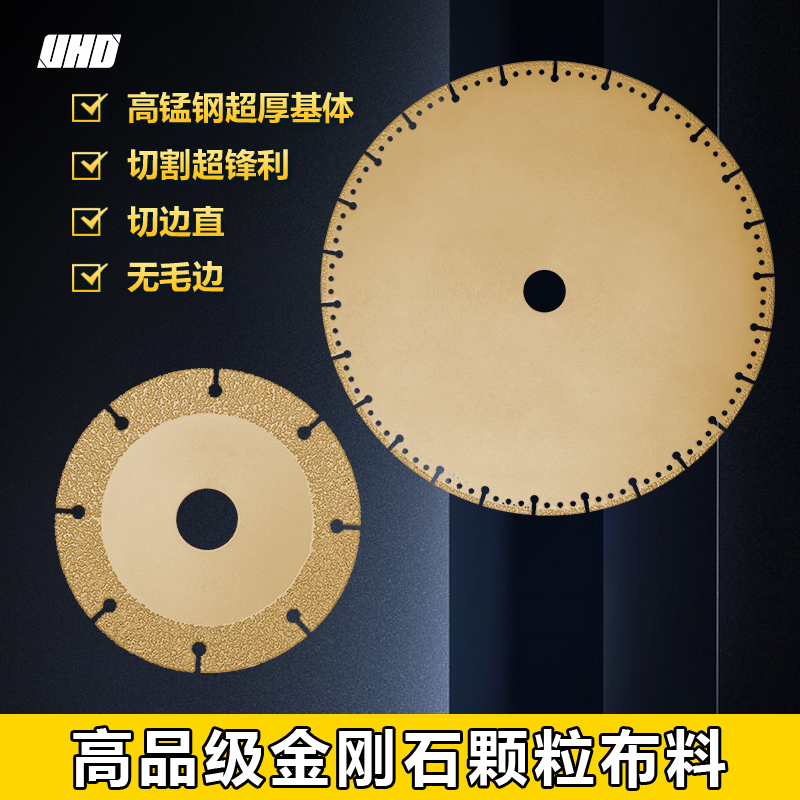

This product is specially designed for efficient and precise cutting of gray cast iron, ductile iron, stainless steel, cemented carbide, as well as complex workpieces such as stone, glass, and ceramics. Using its high-grade diamond particles, the saw blade ensures excellent wear resistance and sharpness, making the service life of a single diamond saw blade much longer than that of a traditional resin saw blade, and greatly reducing the replacement frequency and operating costs. The ultra-thick matrix design of high manganese steel improves stability and safety during use. The cutting process is sharp and smooth, which reduces the labor intensity of workers and improves work efficiency. At the same time, the amount of dust generated is small, which reduces the environmental burden and optimizes the hygienic conditions of the workplace. The precise size and tooth shape design, as well as the promised powerful cutting capacity, make the brazed diamond saw blade 400 a reliable cutting tool on the market.

Advantages and features

1. Ultra-sharp cutting: using high-quality diamond as abrasive to ensure sharp cutting performance.

2. The cutting edge is straight and burr-free: Optimized tool design and precise manufacturing process ensure that the cutting surface is straight and smooth without the need for subsequent processing.

3. Less dust: Less dust is generated during the cutting process, which helps create a more environmentally friendly working environment.

4. Extra-thick high manganese steel carcass: Extra-thick high manganese steel carcass is used to improve the safety and durability of the saw blade.

5. Labor-saving and efficient cutting: Equipped with advanced diamond particles and optimized tooth design, it makes the cutting process more labor-saving and improves work efficiency.

6. Extra long service life: It has a longer service life than ordinary resin cutting blades, one diamond saw blade can be used with up to multiple resin blades.

Application Scenario

Diamond saw blades are suitable for cutting high hardness and high wear resistance materials. Specific applications include but are not limited to the following materials:

-Gray iron

- Ductile iron

-Stainless steel

-Carbide

-Stone (such as granite, marble, etc.)

- Glass-ceramic,

Please note that conventional brazed diamond saw blades may not be suitable for all cutting environments and materials. Users should select the appropriate saw blade type and parameters according to specific cutting requirements.