The main parameters

| hscode: | 68042200 |

|---|---|

| Dust-free operation: | No dust or odor is generated during operation |

| safety: | There is no longer than than the following: |

| product code: | 12 |

| Durable life: | 100 times more durable than traditional resin bonded tools |

| Improved sharpness: | 3 times more efficient than traditional resin bonding tools |

| Product Size: | Multiple size options for high-speed performance needs |

| product name: | Vacuum brazed diamond grinding disc |

| Matrix material: | 45 # steel |

| Processing object material adaptability: | Gray cast iron, ductile iron |

| Product Supply Form: | Standard type and customers define (how the segment is formed) |

| Technical Support: | Provide comprehensive technical documentation and professional advice from the application engineering team |

| Product Series: | Vacuum Brazed Diamond Tools |

| material type: | diamond |

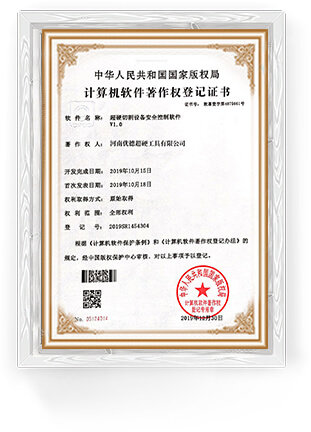

| Quality Certification: | Possess industry-related quality certification |

| Applicable fields: | Metal processing, foundry industry, machinery manufacturing, etc. |

See more